Wooden matches need several elements to light successfully.

English druggist John Walker discovered this fact in 1826, when he invented the friction match. Friction matches work by rubbing two surfaces together to create a small flame, which Walker discovered after dropping a matchstick covered with a chemical solution onto his hearth. When it burst into flame, he saw the practical application and started selling matches.

Friction caused white phosphorus on the match head to ignite another substance, potassium chlorate, which burned slowly enough to light the matchstick itself. White phosphorus turned out to be volatile and dangerous, however, especially to workers in plants where it was used.

In the early 1850s, another Englishman, Arthur Albright invented safety matches. Instead of using white phosphorus on the match itself, Albright’s matches put a less explosive red phosphorus that he had formulated on a strip on the outside of the matchbox.

The safer method of ignition caught on. In 1853, American Edward Tatnall caught wind of the new matches, and formed the Diamond Match Co. in Wilmington, Delaware. Diamond would become the largest manufacturer of matches in the United States by the late 1800s, a title which the company still holds today.

Potassium chlorate became the key ingredient in this particular kind of matchmaking. The substance derives from potash ore, which formed from salts left behind from when inland seas and oceans dried up in ancient times.

Potash mining continues to be big business, with Canada the world’s largest producer. The substance is used mainly for fertilizer, with about 15 percent of it used for a variety of other purposes including, but not limited to matches.

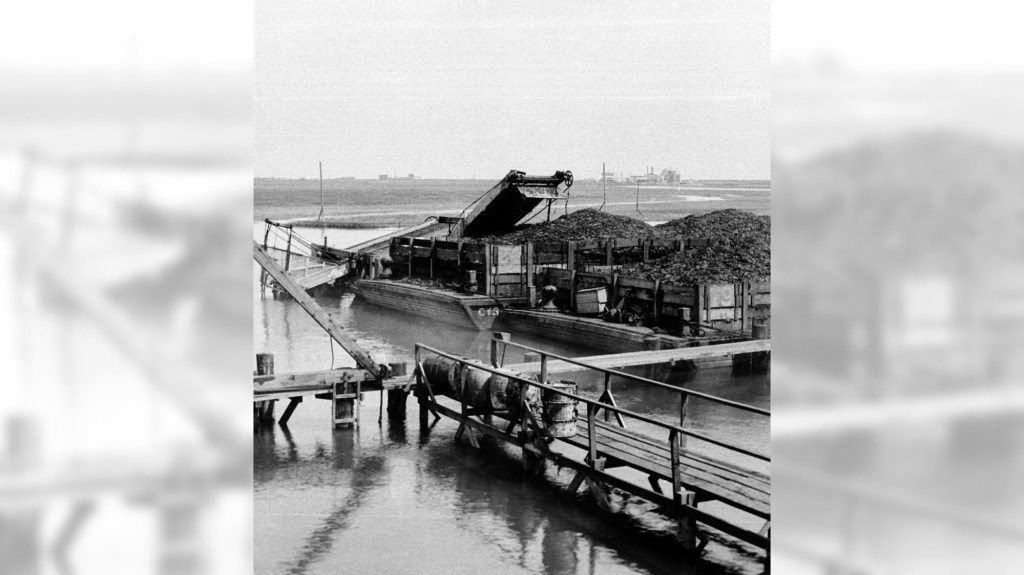

Kelp turns out to be one of the marine sources for potash, a fact known as early as 1719, when offshore kelp beds were harvested and converted into potash in Scotland’s northern Orkney Islands.

With demands for potash rising in the early 1900s, producers began…

Read the full article here